| ||||

| ||||

| Moderated by: Greg Fletcher |

|

||||||||||||||

| Changing front wheel bearings | Rate Topic |

| Author | Post |

|---|

| Posted: 08-16-2016 05:59 am |

|

1st Post |

|

NigelK Member

|

Dear all Although my GT passed its MOT inspection a few weeks back, the tester commented on the slight play in the front wheels and suggested I adjust the front wheel bearings. I did this last weekend (using the Haynes Vauxhall Magnum WSM rather than the J-H WSM, as the latter is pretty sketchy on this job) but there is still play in the front wheels both side-to-side and top-to-bottom. I've decided to change the front wheel bearings and have just bought the relevant parts from Martin Robey here in the UK. The Haynes manual includes a comprehensive guide to the job, and it looks pretty straightforward. Aside from a couple of aspects, namely a) whether the inner bearing oil seal is the early larger type or the later smaller type with the separate metal shield collar, and b) whether the bearings should be packed with LM grease (Haynes manual) or not (J-H WSM). Any thoughts on these the issues? Are there any pitfalls to the job that I need to be aware of? Many thanks in advance for all advice / comments. Best wishes, Nigel

|

||||||||||||||

| |||||||||||||||

| Posted: 08-17-2016 01:40 pm |

|

2nd Post |

|

redracer Member

|

Nigel: I don't know what others do, but on all the "later" styled seals with the separate shield, we retrofit them with the earlier "standard" seal-inside-the-metal-casing. The later style did NOT give very good protection from the dust and dirt, which is going to wear down the bearing and more importantly, the spindle the bearings ride on.

|

|||||||||||||

| ||||||||||||||

| Posted: 08-20-2016 02:17 am |

|

3rd Post |

|

Screenplay Member

|

Nigel, Many years ago a machinist told me that it's a good idea to always put the outer bearing races in the freezer for some time (few hours) before tapping them into place. It "shrinks" the steel ever so slightly and they'll go in easier. I've always done it though to be honest I don't know if it really helps or not. Perhaps someone with more knowledge could chime in? Regarding grease, I've always used the lithium stuff. I can't believe that using other greases specially manufactured for bearings would present a problem in any way, but perhaps one will provide better protection than the other in the long run. Clinton Last edited on 08-20-2016 02:29 am by Screenplay |

||||||||||||||

| |||||||||||||||

| Posted: 08-20-2016 03:13 am |

|

4th Post |

|

redracer Member

|

Any grease with MoS2(Molybdenum disulfide) should help as it can take extreme pressure.

|

|||||||||||||

| ||||||||||||||

| Posted: 08-21-2016 01:47 pm |

|

5th Post |

|

NigelK Member

|

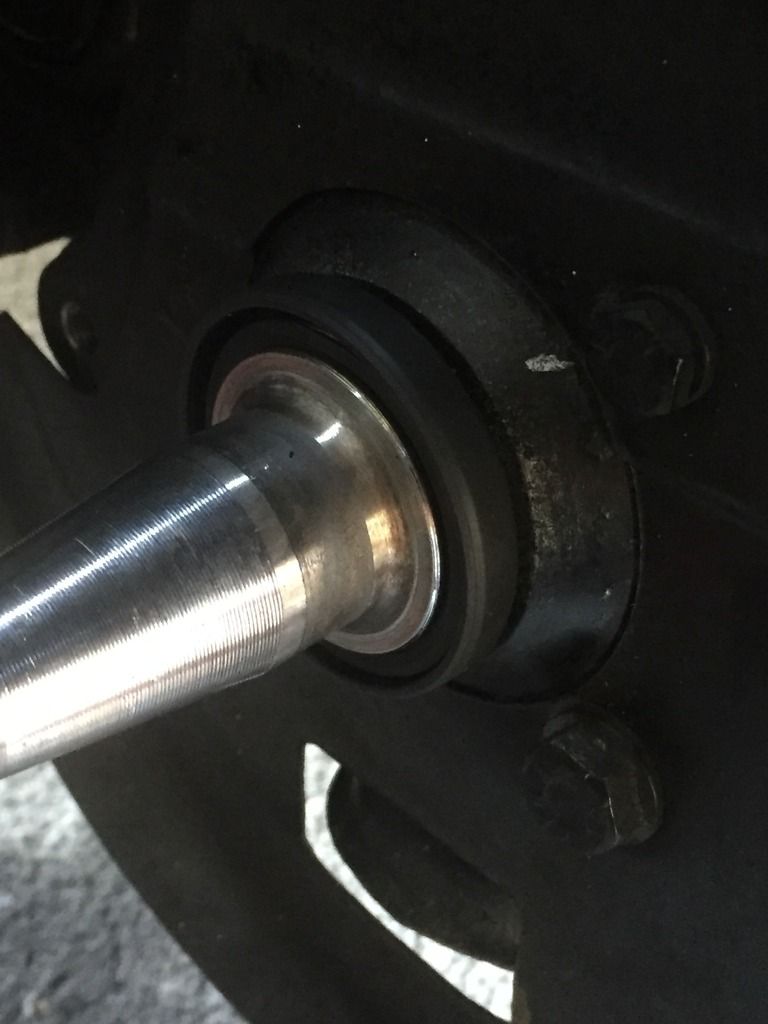

Thanks all. Turns out my GT indeed has hubs with the later metal collar (shield) and small rubber seal. The new hub oil seal is very different, a hard rubber ring with a spring-loaded lip. Here are some photos:  Question is, how do I install this seal? No instructions came with it. Do I press it onto the widest part of the spindle like this?  Or do I press it into the hub like this (NB in this photo I have not pressed the seal all the way into the hub, just in case I need to remove it again and risk damaging it)?  Any advice much appreciated... Last edited on 08-15-2017 08:46 pm by NigelK |

||||||||||||||

| |||||||||||||||

| Posted: 08-21-2016 02:19 pm |

|

6th Post |

|

Brett Gibson JH5 20497 Member

|

Put the seal into the hub, and seat it properly, trying to put it on the shaft and getting the seal to sit in the hub would be a disaster.

|

|||||||||||||

| ||||||||||||||

| Posted: 08-21-2016 02:24 pm |

|

7th Post |

|

NigelK Member

|

Thanks Brett. So is the seal going to remain stationary relative to the hub and, therefore, rotate relative to the spindle? In which case I should smear the lip and inner surface of the seal with anti-scuffing paste? Or is the seal fixed relative to the spindle and the hub rotates around it, in which case I should apply the paste to the outer surface of the seal?

|

||||||||||||||

| |||||||||||||||

| Posted: 08-21-2016 03:51 pm |

|

8th Post |

|

redracer Member

|

Nigel: some rubber grease on the mating surfaces(both outer and shaft sides) will make installation easier. MOSS motors sells a jar of it(read "lifetime supply") of it fairly inexpensively.

|

|||||||||||||

| ||||||||||||||

| Posted: 08-22-2016 01:40 pm |

|

9th Post |

|

Brett Gibson JH5 20497 Member

|

The seal rotates fixed with the bearing hub, a small smear of whatever grease you are packing the bearings with on the lip, and body of the seal (helps with pressing the seal into the hub) is all you need. Just make sure the sealing surface the lip rides on is clean and free of deformities. A bit of steel wool can be used to clean it up, but makes sure it's a clean surface when done. Good luck.

|

||||||||||||||

| |||||||||||||||

| Posted: 08-22-2016 01:58 pm |

|

10th Post |

|

NigelK Member

|

Thanks all. Job done. Successfully (I think). Just need to wait for my son to get home so he can help me bleed the front brakes (had to disconnect the brake lines to remove the calipers) and then I can road test!

|

|||||||||||||

| ||||||||||||||

| Posted: 08-22-2016 02:09 pm |

|

11th Post |

|

redracer Member

|

Nigel: you reminded me in your last post; we always cut a "V" notch in the tab next to the calipers where the brake line runs through so if the bearings need to be done, all you need to do is loosen the locking nut and "hang" the calipers wherever, thus avoiding having to bleed them again. A carborundum cut-off wheel on a Dremel tool does the job nicely.

|

||||||||||||||

| |||||||||||||||

| Posted: 08-22-2016 03:21 pm |

|

12th Post |

|

NigelK Member

|

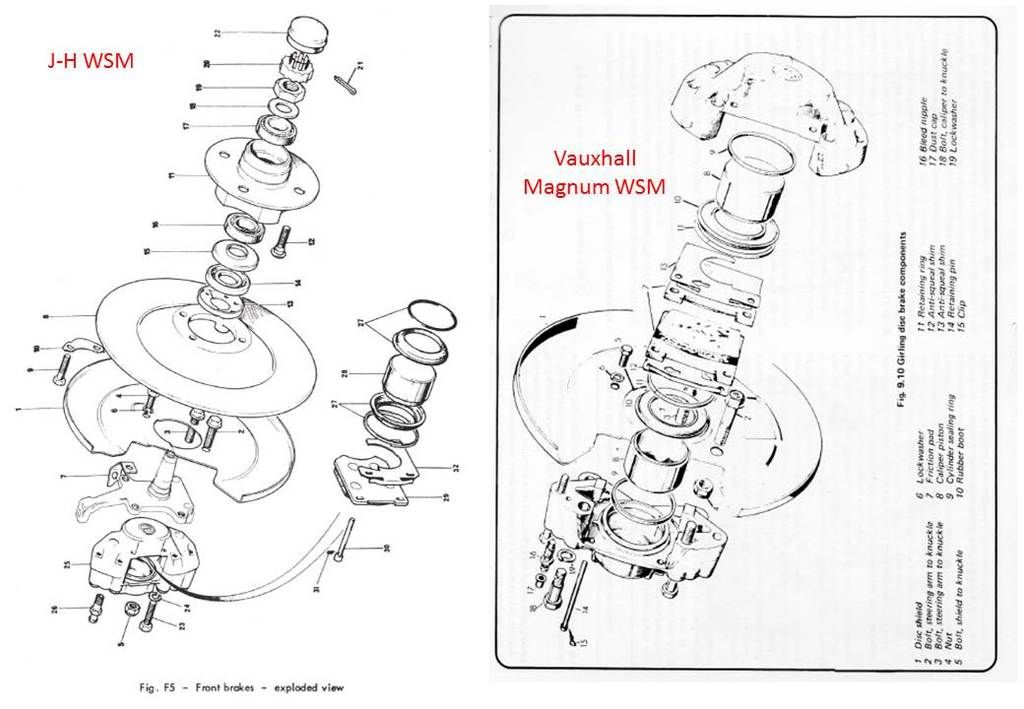

Good tip. Shame I don't have a dremel tool. I also noticed that the anti-squeal shims had been fitted the wrong way round. The J-H workshop manual actually shows them in the incorrect orientation, while the Vauxhall Magnum Haynes workshop manual has the correct orientation. Please see the below: The text in both the J-H and Vauxhall WSMs does state that the shims should be fitted with the arrows pointing in the direction of wheel rotation. It's just the J-H WSM diagram which appears wrong... Last edited on 08-15-2017 08:47 pm by NigelK |

|||||||||||||

| ||||||||||||||

| Posted: 08-22-2016 03:33 pm |

|

13th Post |

|

redracer Member

|

Good you figured the diagrams out. As for the brake line tab, a hacksaw will work-metal is thin

|

||||||||||||||

| |||||||||||||||

| Current time is 12:15 am | |

| > Jensen Healey & Jensen GT Tech > Suspension > Changing front wheel bearings | Top |