How Plastigauge

Works

(courtesy of PlastigaugeUSA.com)

Plastigauge is a great product for checking bearing clearance in your

engine or any place where measuring a hidden clearance is required.

It's also used for numerous industrial applications. It is comprised

of a rod or thread of a compliant plastic material of accurately determined

cross-section - either circular or square.

The surfaces between which measurement is to be made are first separated,

Plastigauge is inserted (see fig. 2) and the surfaces are returned to

their standard position.

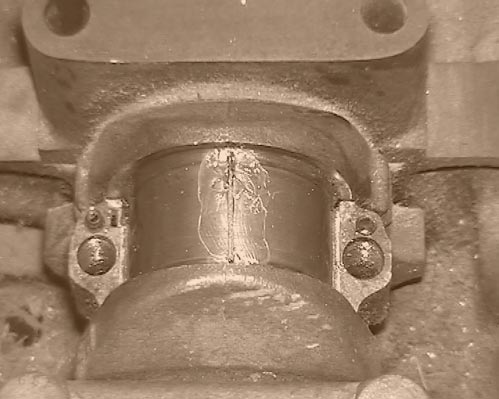

Fig.1 . It is recommended that surfaces be clean prior to use of Plastigauge

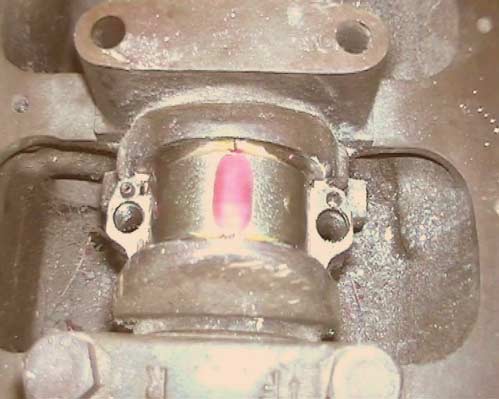

Fig.2 . Plastigauge placed across the bearing surface

The once circular (or square) section will have been flattened but the

area of the cross-section will remain unchanged. We can, therefore,

state that:

or in the case of a square section of side 'a' :-

Here T, the clearance to be measured is equal to a constant divided

by the width of the strip after deformation. By opening the surfaces

to reveal the deformed gauge, W can be measured directly and from this

the clearance, T, can be determined.

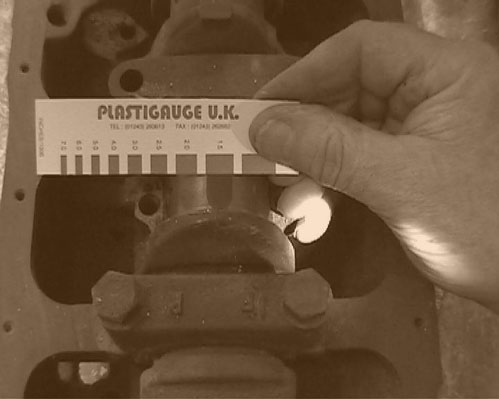

Fig. 3 De-formed Plastigauge ready for measurement

In practice the need for this calculation is obviated by the use of

a calibrated scale on which an array of marks has been printed (see

fig. 4).

Fig 4. De-formed Plastigauge compared with calibrated scale.

The width of the strip can be compared with the scale (see fig. 4).

The actual clearance is shown alongside the mark which most nearly corresponds

to the width. For greater accuracy the clearance may be interpolated

between the two most nearly comparable scale marks.

APPLICATIONS

Plastigauge

is highly effective for measuring the clearance in almost any bearing

configuration or area that has hidden surfaces.

Shaft end-float lends itself to direct measurement by Plastigauge.

Flatness and clearance in pipe-flanges and cylinder heads are readily

checked and measured with standard Plastigauge.

It is recommended that the surfaces be separated by a ground spacing

washer or shim of (typically) 0.002". The gauge is positioned

in those regions where distortion is suspected and any variations of

flatness will be shown, after the assembly is dismantled, by variations

in the width of the compressed strip.

For large bearings, multiple measurements are recommended by inserting

two or more gauges around the bearing.

Plastigauge is particularly effective for the measurement of separation

in moulding tools, and wherever it is required to determine the separation

between hidden surfaces.

A widely used application

Perhaps the

most widely used application of Plastigauge is in the measurement of

clearance in plain automotive bearings. This application is described

in detail:-

Remove the engine sump cover to reveal the big-end and its retaining

set-screws. Remove surplus oil and release the big-end shells by unscrewing

the set-screws. Apply a smear of grease to the journal and small quantity

of silicone release agent to the shell.

Trim a length of Plastigauge to fit across the journal using the grease

to hold it in place. Replace the shell and tighten the set-screws to

the recommended torque setting - without rotating the journal.

Now remove the shell to reveal the Plastigauge which will have been

spread across the bearing surface as a stripe or band. Match the width

of the stripe against the calibrated gauge card supplied and read off

the clearance.

Ideally you should remove the Plastigauge stripe with a clean oily cloth

or industrial de-greasing solvent, but users may be assured that any

Plastigauge left behind is oil soluble and cannot harm the engine in

any way.

Click here for PlastigaugeUSA. You can buy individual packs or boxes for commercial and industrial applications or purchase smaller packs at the Club Store.

main | jensen | tech | people & places | marketplace | message board | join | garage | links | club store