| ||||

| ||||

| Moderated by: Greg Fletcher |

|

||||||||||||||

| Distributor pulley drifting forward on shaft | Rate Topic |

| Author | Post |

|---|

| Posted: 07-21-2020 05:17 am |

|

1st Post |

|

discogodfather Member

|

I have this nagging problem since I rebuilt her recently. The distributor pops out of the socket sometimes, the tach goes dead and the car coasts to a standstill. First time it happened I was on the freeway and almost died, lol. I clamped the distributor down harder and it happened again yesterday at a fairly high rpm. At first I thought clamp, but as I looked closer I realized the actual pulley had drifted forwards about 1/4" or a bit more. It's enough to disconnect the distributor, and there is no looseness of problems with the pulley. The whole shaft is drifting forward over time. I give it a few taps with a hammer and a screw driver and it's back in place. Tried looking at the parts diagram for the aux housing and the shaft. What is holding this thing in place? All I see are some clips on the shaft, there is no bolt or washer holding anything in place that I can see. Why would the shaft drift? Is it overcoming those clips somehow? I ordered a new clamp off ebay just to make sure, the entire dizzy pulley/ shaft/ housing / oil pump is in great shape, so hoping I don't have to completely take it apart and rebuild it somehow. There are a few entire assemblies available on ebay, thinking of getting a spare anyway. Anyone have this drifting forward of the shaft problem?

|

||||||||||||||

| |||||||||||||||

| Posted: 07-21-2020 02:49 pm |

|

2nd Post |

|

redracer Member

|

Disco--not good. There is something amiss inside your auxiliary oil pump housing. Almost sounds like the rear circlip holding the rotor on is moissing, plus the 1/4"movement is not good for the timing belt. Unless there is something obvious externally that is not bolted down, you would be best advised to remove the assembly and investigate(ruined engine:$$$$$$$$$$). While you have it out, shim the pressure relief valve up to 6mm(use shims/washers behind the spring) for the 10psi/1000rpm standard(they sey it originally at 55 psi--too low)

|

|||||||||||||

| ||||||||||||||

| Posted: 07-21-2020 10:32 pm |

|

3rd Post |

|

Esprit2 Member

|

Disco, The auxiliary shaft goes through the oil pump's rotor, and is then secured with a strong little circlip (Item 13 in the attached JPEG). If you want to take it off, plan on a fight. With the rotor on the shaft, it's like a big nail, and that head (the rotor) is not going to pull forward through the housing. If the auxiliary shaft is moving forward at all (end float is only 0.0005"-0.0015"), much less disengaging the distributor, then that circlip must be missing. Or, the rotor has really made a mess of of the inside of the auxiliary housing. Correcting that... or even just investigating it... will requiire removing the auxiliary housing from the engine for further dis-assembly. Have Fun, Tim Engel Attachment: 00000025 - Aux Housing, Oil Pump, Altntr Mount - Illust - 97kb.jpg (Downloaded 59 times) Last edited on 07-21-2020 10:35 pm by Esprit2 |

||||||||||||||

| |||||||||||||||

| Posted: 07-21-2020 11:50 pm |

|

4th Post |

|

discogodfather Member

|

I'll be taking it apart, also buying a spare. Seems like a disaster waiting to happen.

|

|||||||||||||

| ||||||||||||||

| Posted: 08-01-2020 03:23 am |

|

5th Post |

|

discogodfather Member

|

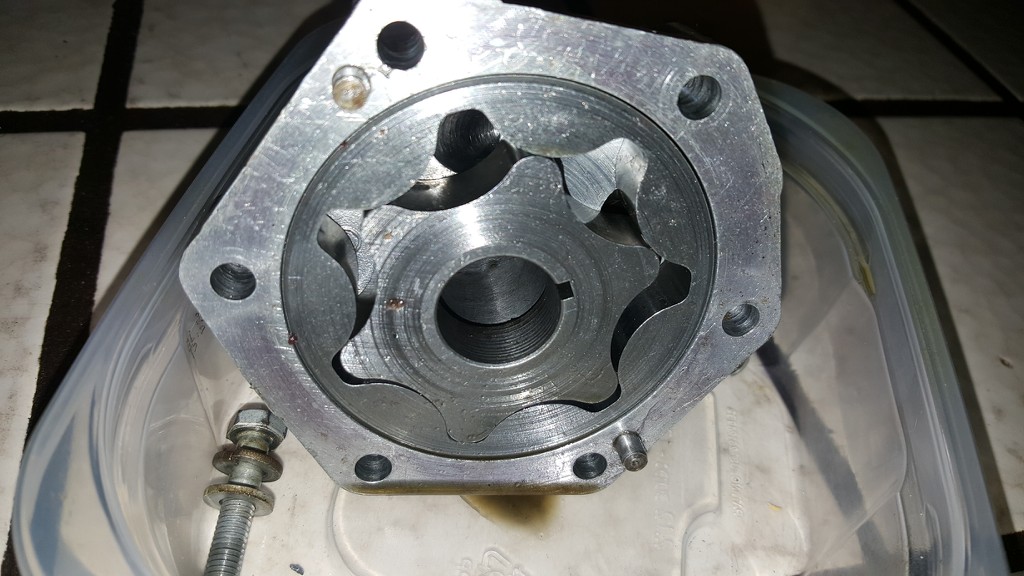

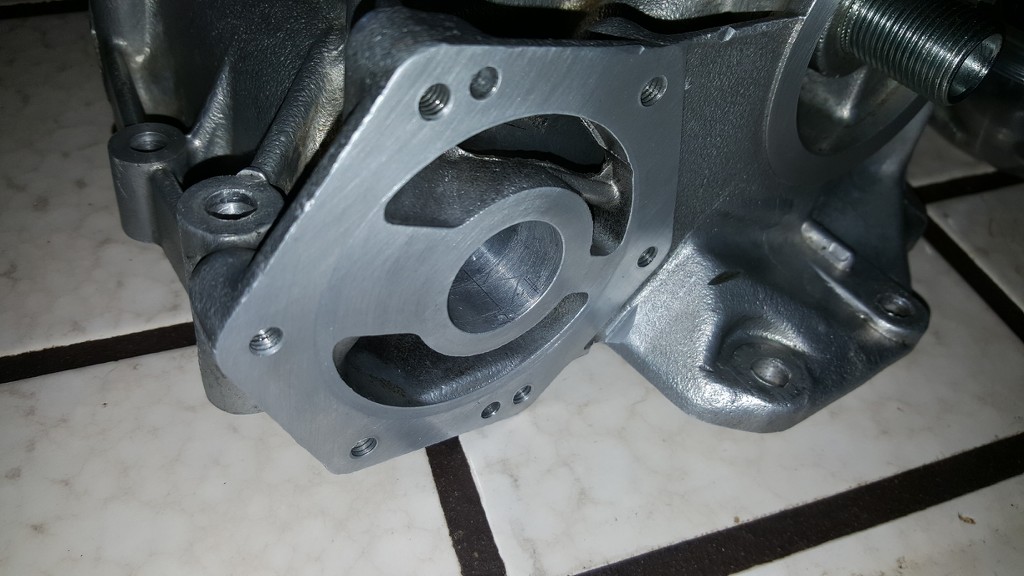

Took it all apart finally and the entire shaft basically dropped out with a little tap on the distributor end once I got the assembly off the car. The scary thing about this Lotus design is the entire thing appear to be held together by that little circular clip by the oil pump rotor. Mine was ovaled and had definitely begun to drift out and this the shaft was drifting. That little clip keeps the shaft in place : 1) Oil pump depends on it staying in place 2) Distributor depends on it staying in place 3) Engine timing (timing belt) depends on it staying in place I know Chapman was a hound for efficiency and everything doing multiple things but this is ridiculous. The oil pump rotor and annular looks ok but I have to differ to experts since there is a wear pattern on the faces and also on the corresponding faces in the housings. Around .001-.002" of a circular wearing pattern. Is this ok to reuse? Also, I have heard of some "high flow" pumps out there, is that worth it? Maybe Gary Kemp?

|

||||||||||||||

| |||||||||||||||

| Posted: 08-04-2020 05:49 pm |

|

6th Post |

|

Greg Fletcher Administrator

|

I’ve found the front and back circlips on the shaft to be fairly robust, I don’t think there is anything inherently wrong with the design. That said, I think it would be time well spent to replace it if anyone is rebuilding an engine. I would also replace the pulley to shaft key as well. I had one actually break on the ignition pulley once and that was a frightening thing to watch. I can’t tell if your pump is serviceable or not, it doesn’t look all that bad. I would just clean it up, put it back together and see what kind of oil pressure you have.

|

|||||||||||||

| ||||||||||||||

| Posted: 08-04-2020 06:30 pm |

|

7th Post |

|

redracer Member

|

Disco: while you have it off, I would definitely shim the relief valve(just under 6mm, max). I have sent you in private email the ypdates for the pil pressure relief ho;e as I could not tell from th epix if it had been done.

|

||||||||||||||

| |||||||||||||||

| Posted: 08-04-2020 11:11 pm |

|

8th Post |

|

discogodfather Member

|

Greg Fletcher wrote:I’ve found the front and back circlips on the shaft to be fairly robust, I don’t think there is anything inherently wrong with the design. I'm not sure if this pump is some kind of early variation, but it seems to only have 1 clip holding the pump rotor on the shaft. It's not really a circlip, it's a snap clip that is round without any ears with holes on it. There is no clip that sits on the back of the rotor, it just butts up to a shoulder on the shaft. I see in parts diagrams that (maybe a newer version?) has two circlips, one in the front and one in the rear of the rotor?

|

|||||||||||||

| ||||||||||||||

| Posted: 08-05-2020 12:32 am |

|

9th Post |

|

redracer Member

|

yes; there are 2 circlips; the one in the rear that keeps the shaft/rotor/ etc from moving forward, and the one in front that keeps the sprocket from moving towards the rear. Apparently, your one in the rear has "ovaled"??; replacing the "slightly" worn parts would be a good idea--probalbly easier/cheaper to replace the auxiliary housing in its entirety.

|

||||||||||||||

| |||||||||||||||

| Current time is 03:29 pm | |

| > Jensen Healey & Jensen GT Tech > Ignition > Distributor pulley drifting forward on shaft | Top |