| Moderated by: Greg Fletcher | ||

| Author | Post | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

martl Member

|

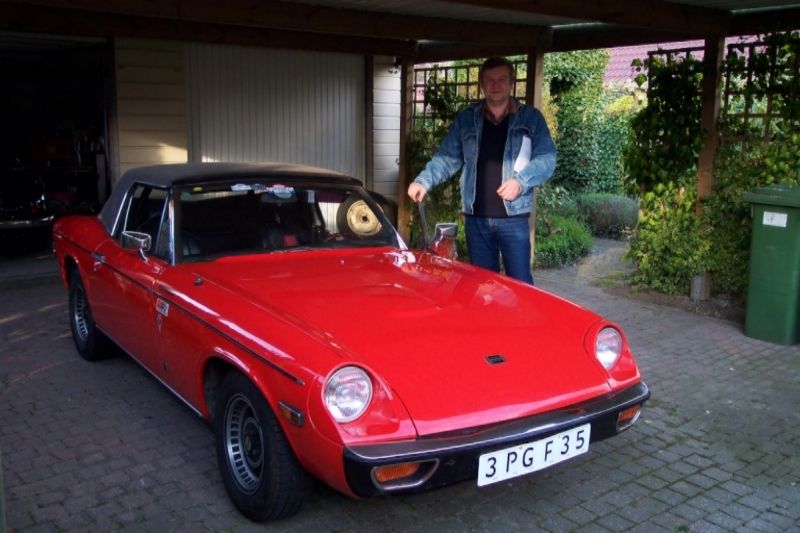

I bought Jensen Healey eight years ago from Holland. The car was great runner, and I drove it home without any problems. The first run from Rotterdam to Rostock Germany was about 700 km and then with ferry from Rostock to Tallinn. Because I have difficulties with the English language my point is - One picture says more than a thousand words ;-) Happy new JH owener in Holland  JH in the new home  First year I took part in several events for historic cas in Estonia and Latvia.    |

|||||||||

|

martl Member

|

I decided in the autumn make a little cosmetic repairs. The lower part of rear fenders was littlebit rusty..... After a bit of a deeper investigation wiev was following:   further exploring results:      After that I lost motivation for a long time :( |

|||||||||

|

martl Member

|

After the year I decided to continue the work with the car. After media blasting:  That picture is probably familiar to everyone who owns JH Next I buy MIG welder and to let make new floorpans by my drawings:  First welding test in my life:  Start measurement and cutting:    Next replacing the out cuted floor sheets:  Old crosmember back and new in place:  The floor almost done:  |

|||||||||

|

martl Member

|

Next job was preparation and installation rocker panels. Cut out the old outer panels:  Repairing the inner sill:  Making new outer panel:   Ready to install:   The job done:  |

|||||||||

|

Tim Murphy Member

|

Wow, very good and skillful work. Congratulations. |

|||||||||

|

answerman Member

|

You're right, this does look familiar. Nice job! I've done pretty much everything you've done, repairing rust in the exact same places, except for the floor pans which is this winter's project (drivers side is done, passenger side is in progress). |

|||||||||

|

Art DeKneef Member

|

Yes, very familiar. Been there, done that. More than once. Nice looking work. |

|||||||||

|

Lash Russell Member

|

Very, very NICE! Thanks for sharing, we are not alone. Lash |

|||||||||

|

martl Member

|

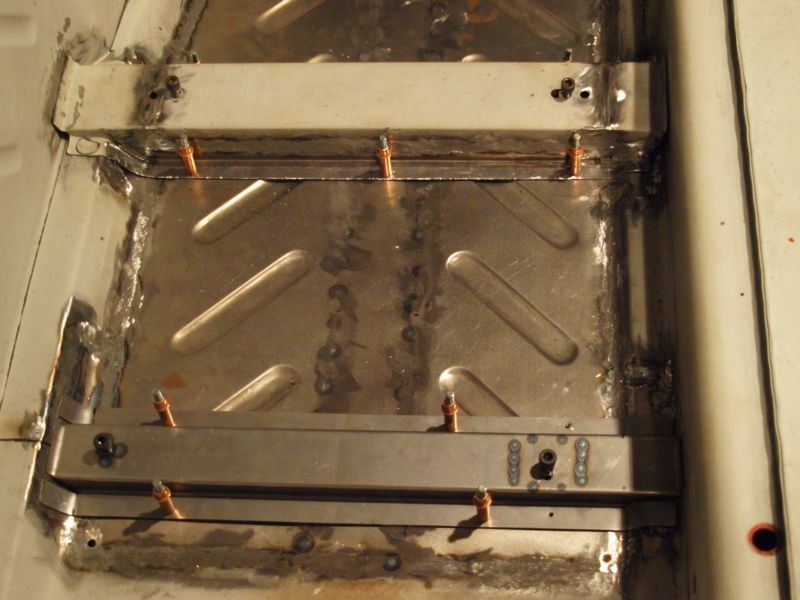

More weldings Under the battery:     the cut out material:  welding work are done and coated with 2 component primer:   In conclusion: chassis bodywork by Greg`s difficulty scale 1/2 vino maybe one beer :-)  |

|||||||||

|

Screenplay Member

|

Martl; Thanks for sharing the pics of your efforts. It is quite an impressive body of work. Clinton Last edited on 01-21-2016 08:52 pm by Screenplay |

|||||||||

|

martl Member

|

Rear wings I put all together for repairing wings:  Someone had tried before:  For welding I cut rusted part:  and weld new:     |

|||||||||

|

martl Member

|

Front wings    |

|||||||||

|

martl Member

|

Trunk lid      |

|||||||||

|

martl Member

|

Hood Typical damage for JH hood:      |

|||||||||

|

martl Member

|

Paint job First chassis painting:   Coating the floor base:  Painting the inner side of wings:  slightly filler:   Finally all bodywork done :-)  |

|||||||||

|

martl Member

|

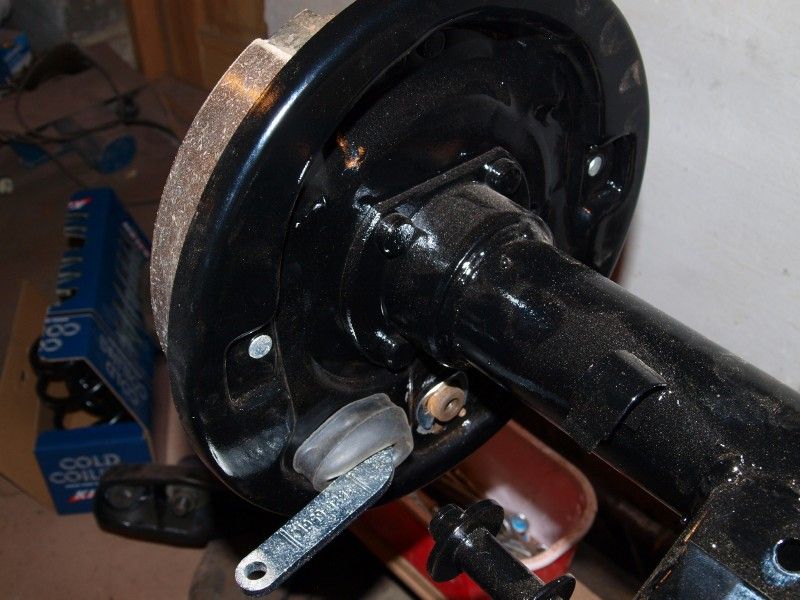

Front axle      |

|||||||||

|

martl Member

|

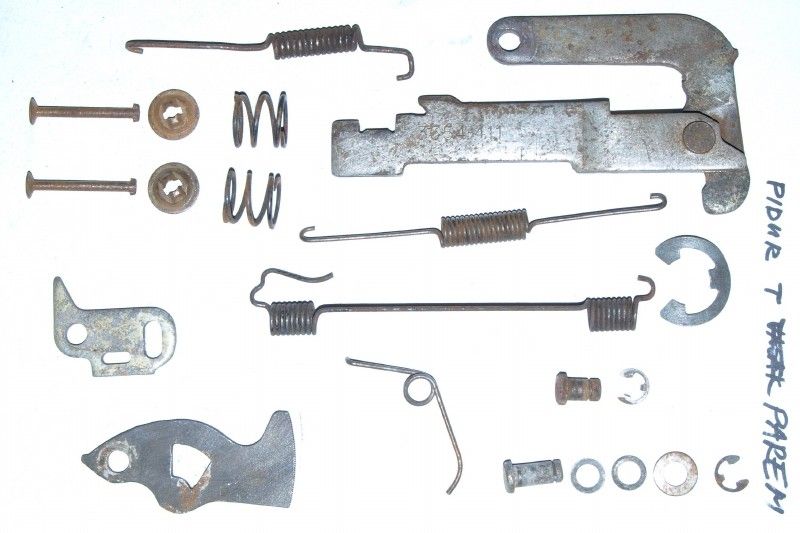

Rear axle     |

|||||||||

|

martl Member

|

details galvanizing    |

|||||||||

|

martl Member

|

Pedalbox     |

|||||||||

|

martl Member

|

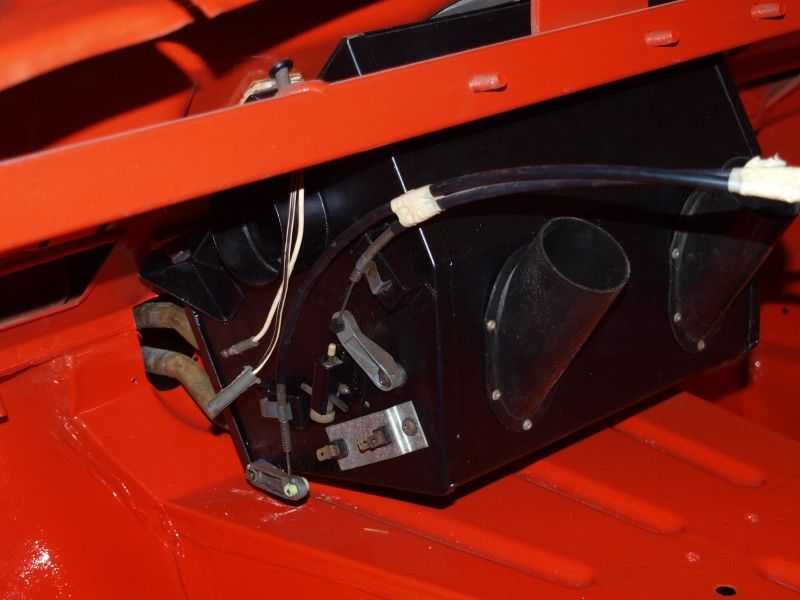

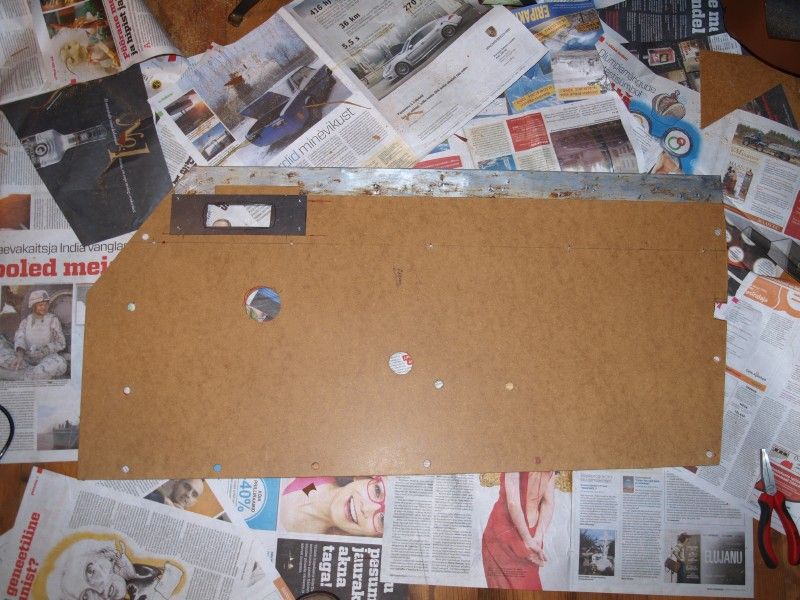

Heater      |

|||||||||

|

martl Member

|

Wiring wiring loom      |

|||||||||

|

martl Member

|

Seats       |

|||||||||

|

martl Member

|

Door panels        |

|||||||||

|

martl Member

|

Engine. Engine stand nearly five years in the corner of garage.  Before I put the engine back, I decided to check the reason of low pressure in first cylinder. First I removed the cylinder head. The view was not the best.   The liners and pistons was worn to last limit.  Cylinder head. The valve guides was worn. The exhaust valves are burned and in first cylinder one inlet valve was twisted. That was the reason of low pressure.  Pulling out the old liners with a self made "JH special tool"  Cylinder block after the first cleaning   |

|||||||||

|

martl Member

|

Engine rebuild First cleaning all engine parts with soda blasting block:   block inside:   other engine parts:  painted cam covers:  |

|||||||||

|

martl Member

|

Assembling the engine new liners  grinded crank  crank on place with new bearings  new Omega pistons   cylinder head  cam follower with HTD tooth pulley    engine done  |

|||||||||

|

martl Member

|

Gearbox JH and Toyota W58 gearbox  What is inside W58?  new linkage   redesigned gearshift mounting  horrible Toyota gearshift and home-made new clutch release bearing  JH and W58 shifter  and "JHW58" shifter  integrated Toyota gearbox, Lotus clutch housing, JH clutch fork and home-made bearing  gearbox is ready  Last edited on 02-06-2016 07:36 pm by martl |

|||||||||

|

subwoofer Member

|

I am massively impressed with your work, it is all looking very nice! It all looks very familiar, including the kinks in the channels under the floor pans. Does every JH have these? I guess they come from jacking the car in the incorrect spot. Also, I hope you added some compression to the engine in the rebuild? The new pistons are 9.5:1? -- Joachim |

|||||||||

|

Art DeKneef Member

|

I'll second Joachim comment. Very impressive job. I like what you have done with the transmission work. |

|||||||||

|

martl Member

|

subwoofer wrote

I odered the pistons from SJ Sportscars and I do not know exactly are the compression 9,5:1 or 8,4:1. Steve from SJ Sportscars recommended that pistons and liners for rebuilding my engine. Some more work Engine and gearbox connected:  engine back the right place:   Rebuild the carbs:   New drive shaft - in one end JH and other Toyota   The old exhaust system:  New welded from different parts:   Engine is ready for the first start after rebuilding:  It start-up !!!!!!!! After the first test drive:  |

|||||||||

|

martl Member

|

First setback after test drive. The distributor leaking oil :-( Needed to replace the oil seal:  Then came the winter ...............  extra insulation for garage door  Now I waiting for spring again |

|||||||||

|

martl Member

|

It was a "short" story of my eight years journey in the wonderful world of Jensen Healey. Thanks, Mart |

|||||||||